A Pharma Process Engineer needs a full understanding of all key production and quality data.

Process Engineers need to ensure production meets strict quality standards by understanding key metrics, quickly identifying and addressing issues, and delivering results that pass regulatory checks.

In order to do their job effectively, they need to be able to answer questions such as:

Deviations

Are there any deviations in critical process parameters?

Optimisation

How can bottlenecks be identified and alleviated to increase throughput?

Trends

Are there any trends in the QC data indicating potential OOS results

Expectations

How is current yield compared to expected yield?

The data you need is hidden among the data you don’t

- Batch Production Records

- Yield or Cycle Time Data

- Process Parameter Logs

- OSS Reports

- CAPA logs

- Emissions Logs

- etc

Spread across multiple siloed systems and data suppliers.

- SCADA

- MES

- LIMS

- QMS

- Excel Sheets

- Localised Documents

- etc

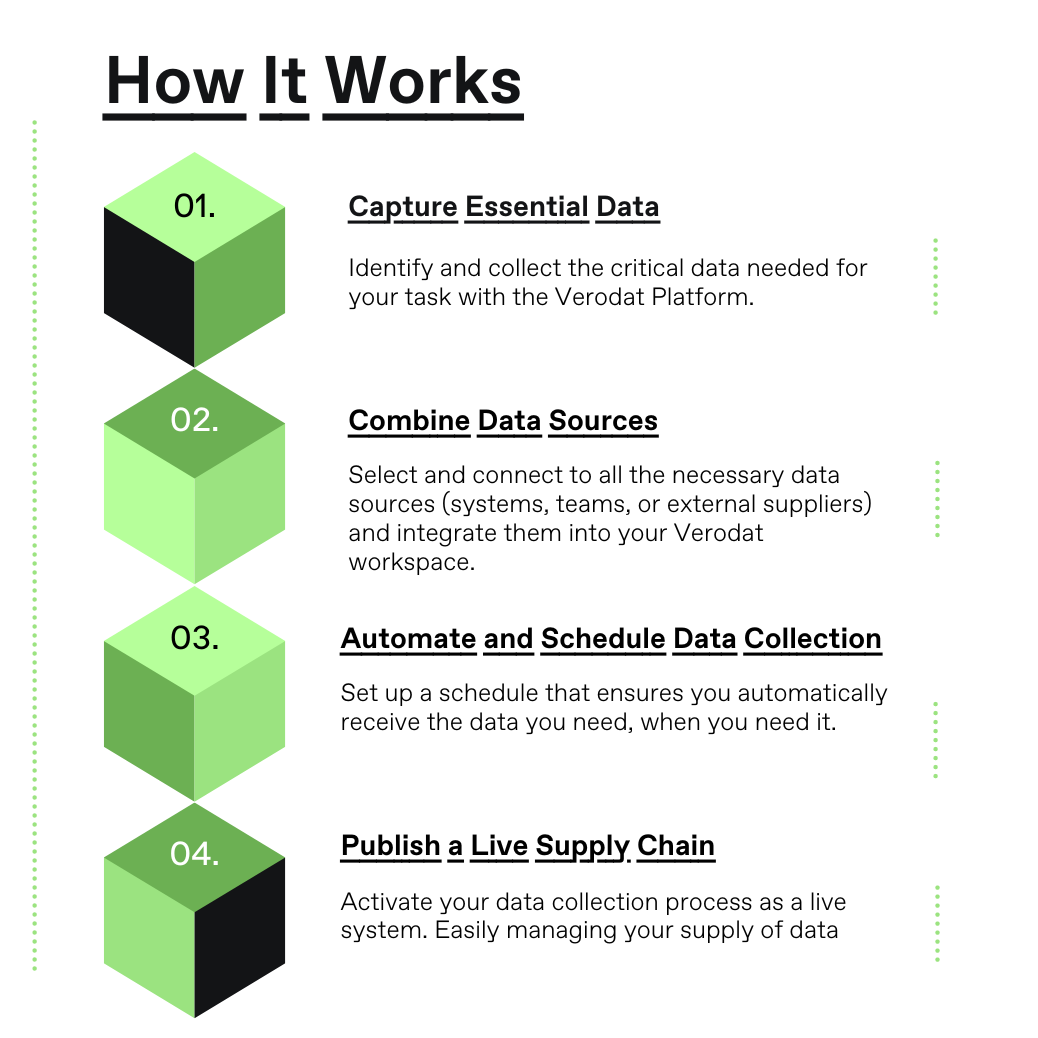

How Does Verodat Help?

Verodat provides a platform that allows you to easily bring together all the data you need in one place.

With AI Readiness by design, the data is formatted, standardised and perfected to meet the needs of AI tools.

The outcome? A data layer enriched with context, supply status and attribution, the critical elements needed to ensure AI effectiveness.

A data layer ready to fuel the AI tools you use in your business, efficiently and safely.

With an AI Ready data layer, a Process Engineer can now easily build and share the AI analytics they need to perform their tasks. Answering the key questions quickly and with confidence in the results.

Let’s look at some scenarios of HOW this can be used.

Verodats Excel Add in means that your data can be easily and immediately brought into Excel (or any of the main analytics tools on the market) This gives you the data you need, in a tool you and your team already use, for easy access and review.

With high-quality data now readily available in Excel. You and your team can now use Co-Pilots, in a tool you’re familiar with to find new insights and quickly and efficiently build out new reports without the need for extensive data prep.

With one click, you can navigate to the Verodat data in your workbook, view the supply status and check the provenance of the number right back to a certified audit trail. Ensuring you know where it came from and how, and when, it was created.

With an AI Ready Data Layer, you can easily switch on Excel copilot to run production scenarios to optimise capacity planning, identifying bottlenecks and suggesting how to alleviate them, without the need for analytics building workshops or technical experts to build complex formulas. Empowering Process Engineers to augment their own skill set.

Automate briefing notes sent directly to your colleagues. Easily scaled and personalised per recipient, focus on the key points they need, in a format that suits them. The Plant Manager gets a morning email with information relating to production schedules and the QA Manager gets an audio file with a quick run down of what’s happened.

A Verodat powered chatbot, trained on your AI Ready Data offers a chat interface where your colleagues can ask questions of the data and receive natural language responses. If a question like ‘What is the current defect rate, and how does it align with quality targets?’ comes up in the meeting, they can simply ask the chat themselves and get a verified answer in seconds.

When your team is using the Verodat chatbot to ask additional questions on your reports, you can analyse questions being asked and log and track them in Verodat. This will help you uncover what data your team need to do their job and easily add additional personalised reports based on these regular queries.

With AI ready data and a trained model managed by Verodat, AI can automatically classify deviations, suggest root causes based on historical data, and even propose corrective actions. You can use AI to sift through deviation reports and identify common trends, helping you focus on high-impact issues. You can automate triggers in your workflows to carry out preventive actions based on your defined criteria – i.e switching off a machine or sending an alert if certain limits are reached.

AI-based predictive maintenance systems can forecast equipment failures before they occur, based on sensor data and historical performance. For example, flagging when critical equipment like centrifuges or bioreactors might fail, allowing for preemptive maintenance.

Verodat makes it easy to defend your decision making and meet your audit and regulatory requirements. Your data in your Verodat workplace has full supply status and attribution included, so you can trace your end reports right back to the point of origin. If you’ve used AI in your reports, the context, supply status and attribution means that the outcomes are fully verifiable, defensible and repeatable.

Verodat can be deployed into your business quickly and efficiently.

Verodat fits seamlessly into the existing tools your team already use and are familiar with, reducing adoption and change management challenges and allowing you immediate access to the benefits of AI.

Verodat offers a new operating model to your business. A simpler, more efficient way to augment your team with the many benefits of both existing AI and future innovations.

To find out more about Verodat, get in touch with one of our experts.